Quality control at Electrofact.

Maintenance at

CERN.

Systems engineer

at CERN.

The Control Data

7600.

System analyst at

l'EPFL, Lausanne.

The beginning of

Personnel Computing.

|

The Control Data Crew

at

CERN

|

Quality control at Electrofact.

As strange as it may sound, in the beginning I did not

want to start “working with computers” as we used

to call this in our region at that time. Anyway we know

all what followed !

It was by chance that the local unemployment office has

sent me a message that there was a job available in “Amersfoort”

in which I could possibly be interested. So I did go

there to present myself, and I finished by signing a work contract

for a job as QA controller for “Control Data”

products at one of their production sites, “Electrofact”

which they bought just a little time before that.

|

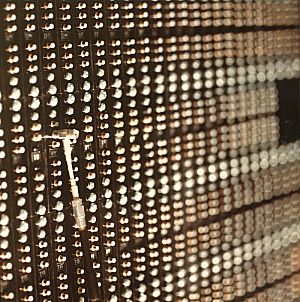

The

main part of this quality control job was to do final control and

verifying of tape drive units. On the picture shown

aside we can see the carrying out a read-head adjustment

procedure.

The

job was rather hard, then on the backside of the chassis, which

is visible on the picture, were a thousand interconnection wires.

This wiring was plugged in by the production crew

and even then when they did their best, dozens of unavoidable

wiring errors of any kind were left in the machines which each

delivery to our QA workshop.

In

order to do this control, we had to follow a specially for this

purpose established checklist, try to find and fix all the wiring

bugs and other errors, make all the necessary adjustments, and

last but not least run a final check on a for that time (1969 -

1971) already little old computer.

On

the Electrofact list where also other equipment's, such as

punched card readers, for the ones who came to computing only

recently, it is the device you can see on the foreground of the

second picture shown aside.

The

model on the picture was able to read about 1'200 cards in a

minute, or 20 cards a second if you want, so imagine cards

stuffing up inside at this speed. It is like toady's

laser printers, you say some unprintable words; open the thing up

and then try to get all stuff out again.

|

|

|

|

Maintenance at CERN.

It was at the end of the month of June 1971 that I have

arrived at the Geneva railway station Cornavin. After

having spent the night in a hotel, a Control Data manager came

to pick me up in order to go to C.E.R.N., where I had started

a job as Customer Engineer.

The initial duration off the contract was fixed for two

years, but I finished by staying in Switzerland from 1971 up to 1995,

which makes up a total of nearly twenty four years instead of the

initial two years.

My job at the C.E.R.N. site was about the same as

it was at Electrofact, with the only difference that here it

was rather preventive maintenance on all sorts of peripheral

equipment's, like the card readers, the card punches, tape drives,

printers and other maintenance tasks.

The computer center was just aside the administrative

building, but moving was planned into a brand-new building elsewhere

on the site.

|

|

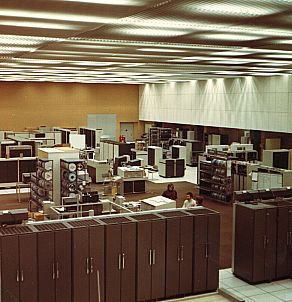

The photographs shown here display the C.E.R.N.

computer site of that time.

The first picture shows the section where the

mainframes themselves were installed, the second shows some of

the Control Data crew occupied with a preventive

maintenance task, and the last picture shows the section where

the tape drive units were installed.

Ok what me concerned, I as in the beginning not in

charge of the mainframes, therefore we had our specialists.

But after some time time it has become clear that this task

should be spread over several people, then as this was the use at

that time, we had a so called “on Call” service, and

thereby a morning and an evening crew. As result a

to limited mainframe specialist crew, was that those who were

specialist were called out to often.

First my colleagues and me we have learned the first

notions of fixing, identification and repairing of the problems

with the so called “Front-Ends”, the first

tasks were to identify memory problem and to replace the possibly

defective modules.

After a while, the more and more we have got

involved with more important tasks, like installing so called

“Field Change Orders”, this were corrections

done to the hardware wiring, what Control Data usually

installed afterwards. First you should take out

exiting wires. This sounds more simple as it was,

then you should imagine that the wiring map was usually a dozen

centimeters thick ore more.

Under this conditions it was not very easy to take out, p.e. a

wire from module K18 pin 22, especially when this one is below a

dozen centimeters of tight wiring, and also attention has to be

paid to that you should not take out the wire aside.

After this more or less introduction period, my

collages and me have been sent for further training in Paris

where Control Data had a training center, for training on

the “Control Data 7600”, which was the

most powerful computer at that time.

|

|

|

|

|

Systems engineer at CERN.

|

Once back from our Paris training we had to practice

what we learned over there, and now we had also some more rights,

in other words the right to called out at night like the others.

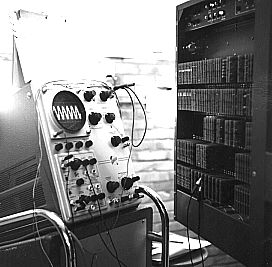

That what you are seeing on the first image aside,

is not a piece belonging to the mainframe or any other processor

or so, no it is a 600 Mo disk drive, which needed also

maintenance so one in a while. For example cleaning

the heads and disk platters, also head replacement had to be done

if they became to weak, verify the hydraulic circuit used for

head positioning, and others...

The second picture shows a session of controlling

the coherence of the machines internal signals. Then

in case of a to big shift between two signals, one should either

try to replace the module, or as alternative change the

wire-length, as anybody knows, electricity travels at light

speed, and about 30 cm of wire make up one nano (10 -9)

second. Very often a wire length change in order of

a meter cleared the problem.

The harder fixing of all of them was the Control

Data 7600 (Photo below), then this one was a RISC type

conception, and was be able to execute several instruction at the

same time, who of course is not not an advantage for problem

diagnosis.

Not

only that the 7600 could execute several instruction at

same time, most of them were treated by separate execution units.

This is maybe very good for the execution speed, but

an absolute disaster when you try fix the thing.

|

|

|

|

The Control Data 7600.

|

|

The Control Data 7600, shown on the picture

here is the machine on which I have spent most of my time in my

last year at the C.E.R.N. site.

In the beginning I have done the same type of work

as the others of the crew, e.g. maintenance, fixing of problems

and the “On Call” service. But

after a while it became the more and more necessary to

familiarize a person of the technical

crew with the internals of the operating system. So

it came that I have spent some time in Frankfort to learn more

about system analysis, system programming and installation.

|

The Control Data 7600 was a machine in conception

very close to what is today better known as a RISC processor (Reduced

Instruction Set

Computer). The 7600

was in fact able to start a new instruction every clock cycle (27

nano-seconds). The main processing unit was split up

into several separate units who could each operate in a individual

manner, and some even could handle several operands in a row.

The memory had an access time of less then 80 nano-seconds, e.g. the

data was available at the third clock cycle (27 nano-seconds) or in

other words between 54 and 81 nano-seconds, thereafter a wait of 270

nano-seconds the memory section was again available. The

7600 had 32 of this memory sections organized in a stripping

manner as we do find today with RAID 0 disk dives. The

memory bus itself had a transfer capacity of 270 Mo / sec.

Whereby the I/O was not done by the main processor, but

the 7600 had ten specialized processors fro that task, it was

up to them to struggle with I/O stuff.

System analyst at EPFL, Lausanne.

Little by little I have made myself more familiar with

operating systems, but also with programming, even when the

programming languages used where not at all the same as the ones

commonly used in business. Then the system itself was

entirely written in a Control Data assembly language and had

no structure in common with the languages used in business.

The second language I have learned that time, is Fortran, but

that was to make various utilities any kind, but was not at system

level.

It was somewhere in the middle of the 80's when I have

been affected to the E.P.F.L. site in Lausanne as systems

analyst, when this position became available.

My initial assignment was to backup the systems analyst

already in place and do compilations and assembly's of the customers

operating system, give follow up on software problems (or bugs if you

want) and other problems. We had also to adapt the

operating system to the customers needs with every release, verify

and add in the local modifications, as well recompile all customer

specific plug-ins. An other task was to analyze

the so called “Dump” ,that were memory listings

which occurred when a important system error occurred.

Sometime we could identify the problem, and the case of a hardware

problem caused always a problem with some of our technicians who

systematically disagreed, however in the other case I had to send the

tape the support center in the U.S.A.

As mentioned above, in the beginning I have backed up

the systems analyst already in place, who was doing also the customer

support part of the job, but when he left the company, it was up to

me to take this over with the help of the software specialist of the

Zurich office.

Towards the end of my “Lausanne” time I have

started to investigate in Micro processor techniques of that time.

There were already some of my colleagues who did have their own Micro

Computer, but what I needed most was something what could do the

communication tasks and what would allow me to download systems

corrective code and small electronic documents. The

method used by my college analyst was to list everything on a

terminal, record it onto a tape, then switch from an external

connection to the internal mainframe and play back the tape instead

of typing it on the keyboard. In order to automate this

type of operation, I had bought myself an small machine equipped with

CPM 80 and a Z80 processor. (yes in

that time we still could choose different systems as

Intel-Microsoft).

It was this little machine who was next programmed to do this kind of

tasks, it was faster, more reliable and a lot easier.

Thereafter my little machine has largely been used to do this type of

data transfer, but I used it also to edit text and programs in

“Off-Line” mode, that means that we create or

modify the texts on the local machine and as following transfer the

whole to the mainframe for processing.

But before all this I had to create the connect scripts

and the data transfer programs for this machine and other utilities.

It has been those operations who have largely

contributed to my actual knowledge of the 'C' programming luggage.

The beginning of Micro Computing.

It was after Control Data closed down his offices

in Suisse-Romande that I have become an independent technician, and

have started thereby investigate more seriously in the subject

Micro-Computing. In fact I could already quickly start

to collaborate with an technical consulting office active in the

construction domain in Wallis where I lived at that time.

I had to update and keep up to date their programs, create new ones,

or even refurbish exiting programs (rewrite them), and following that

prepare the installation procedures. Thereafter I had to

do the install at their customers. Included in this was

also the final user support. There were other obvious

things like follow up of problems. The other thing which

was coming up at that time was final customer support, repair and

general support of MS-DOS systems (some called it MESS-DOS!), what

was not a luxury those days.

After a certain time had to go on with training in order

to get further on professionally, the course chosen was a project

management training who contained all the necessary elements for

business computing and the handling of projects. After

this training I have followed a complementary

training for the Microsoft Windows environment, and the

programming of it.

It was finally during the period from end 1993 up to

beginning 1995 that I have continued my professional training in the

UNIX - ORACLE - NETWORK direction, on which I can add as of the last

years LINUX in self training.

It was during the year 1994 that I have preferred to

continue my activity in France rather as in Switzerland.

Just think, the Paris region has twice as much industries and

inhabitants as whole Switzerland add-up, and 55 times the region of

“Walis” where I used to live. And that was a

to important difference.

|